| |

| |

| |

| |

| |

| |

| |

| |

ISO 9001:2000 |

![]()

|

||||||||||||||||||||

| Characteristics | ||||||||||||||||||||

| Principle of Measurement | ||||||||||||||||||||

| List of Codes for Barflow Tube Model Selection | ||||||||||||||||||||

| Straight Run Requirement of Multi-port Pitot Tube | ||||||||||||||||||||

| High Welding Quality (WPS/PQR) | ||||||||||||||||||||

| Characteristics | ||||||||||||||||||||

Enables substantial energy saving Barflow Tube causes marginal permanent pressure loss by not reducing the pipe section compared with Orifice-type and other differential pressure flow meters. This reduces the operation cost, while saving energy. |

||||||||||||||||||||

Applicable fluids Gas, liquid, and steam |

||||||||||||||||||||

Unique static-pressure ports The unique shape of the static-pressure ports minimizes the adverse effects of Kalman Vortex Shed dings. |

||||||||||||||||||||

Retractable Designs are available Retractable BARFLOW TUBES makes it possible to install and remove without Shutting down the process. |

||||||||||||||||||||

Measurement of average flow velocity With multiple total pressure ports and static pressure ports, Barflow Tubes are capable of providing an average flow velocity, while sensing stable values. (Applied only for the turbulence liquid flow) |

||||||||||||||||||||

All-in-one continuous purged mechanism One of the featured devices JMS offer the unique air purge systems with a Manifold Valve function as all-in-one continuous purged mechanism which eliminates dust, and mist effect on the measurements of the flow. |

||||||||||||||||||||

Low maintenance costs Low maintenance costs, due to the unique shape of the sensor tubes and mechanisms. |

||||||||||||||||||||

| Principle of Barflow Tube | ||||||||||||||||||||

Differential pressure flow meters, which include Pitot Tubes, Orifices, Venturi Tubes, Flow Nozzles, etc., are widely used for industrial measurement due to the simple structure, high accuracy, and reliability. Barflow Tube with a Pitot Tube mechanism is particularly effective in energy saving. |

||||||||||||||||||||

| Mechanism of measurement | ||||||||||||||||||||

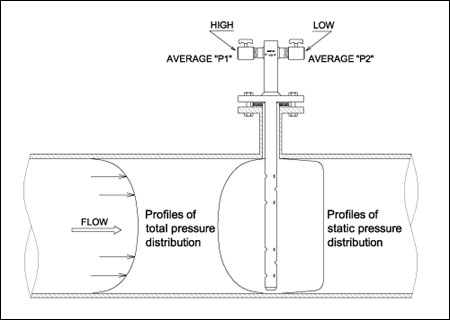

When a Barflow Tube is placed in a flow, the sum of the static and dynamic pressures, or the total pressure (P1), acts on a total pressure port of the tube. A static pressure (P2) acts on a static pressure port on the opposite side. The differential pressure (P1-P2) is measured, which is proportional to the square of the flow rate by Bernoulli's theorem. |

||||||||||||||||||||

|

||||||||||||||||||||

| Comparison with Orifice and Venturi types | ||||||||||||||||||||

|

||||||||||||||||||||

|

||||||||||||||||||||

| List of Codes for Barflow Tube Model Selection | ||||||||||||||||||||

Barflow Tube Models

| ||||||||||||||||||||

| Straight Run Requirement of Multi-port Pitot Tube | ||||||||||||||||||||

| Straight Run Requirement and Locations of Barflow Tube | ||||||||||||||||||||

| High Welding Quality (WPS/PQR) | ||||||||||||||||||||

| 1. Accomplished WPS, PQR system. | ||||||||||||||||||||

| 2. Keep high Welding Quality. | ||||||||||||||||||||

| 3. Welding Inspection by established procedure. | ||||||||||||||||||||

| WPS (Welding Procedure Specification) | ||||||||||||||||||||

| PQR (Welding Procedure Qualification Test Record) | ||||||||||||||||||||

| Copyright (C) 1998-2008 JMS Inc. All rights reserved. | ||||||||||||||||||||